Everything You Need To Know About Mig Welding For Beginner Welders

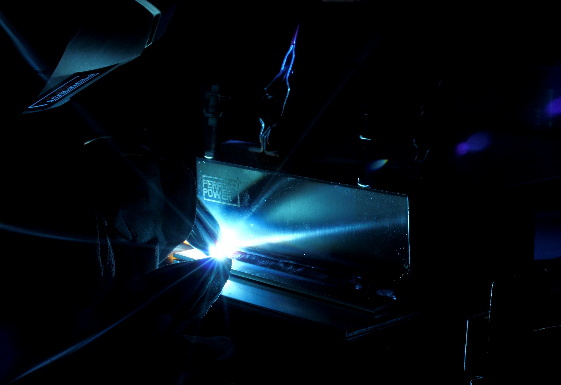

MIG welding is frequently the initial welding technique individuals learn when beginning their welding journey. It is considered one of the simplest and most cost-effective welding methods that is also portable and versatile. Everything You Need To Know About Mig Welding For Beginner Welders

Whether you are a beginner or already attending welding classes, the following five tips can assist you in producing high-quality MIG welds.

Distinguishing Between Good and Bad Weld Beads:

Welders use various kinds of beads, such as stringer, weave, and whipped beads. However, experienced welders are typically familiar with what constitutes a sound and robust weld, regardless of the type of bead used.

Typically, a good weld should exhibit the following characteristics:

- It’s uniform in width.

- The ripples are evenly feathered into the base metal.

- The weld has good penetration.

- There are no signs of gas pockets, porosity or inclusions.

- Signs of burns due to overheating are absent.

Welding school instructors have the ability to display exemplary welds for students to observe.

In contrast, poor welds may possess the following characteristics:

- They may lack uniformity along the weld.

- Bad welds can be too thin.

- They can show cracks down the middle or display discoloration on the base metal.

An incorrect bead profile, lack of fusion, poor wire delivery, or excessive porosity are commonly responsible for producing poor welds.

5 Beginner’s Tips for Making a Good MIG Weld

If you’re considering taking a welding course, hoping to expand your knowledge, or require a quick refresher, the following are five beginner tips for creating a high-quality MIG weld:

Tip #1: Familiarize yourself with the welding gun to feel comfortable while welding.

- As a beginner, wielding a welding gun may not be a familiar task.

- To begin, hold the gun to become accustomed to its weight and positioning. Rest the barrel in one hand and place it on the table, while the other hand operates the trigger.

- The wire should meet the weld at approximately a thirty-degree angle. Stand in a comfortable position with good posture and practice moving the welding gun back and forth over the work surface.

- Practice gently touching the wire to the surface, pulling the gun towards you in a smooth motion at a consistent pace. Once you feel confident, activate the welder by squeezing the trigger and repeating the same movement.

Tip #2: Ensure your metalwork surface is clean before welding.

- It is crucial to clean your metal work surface before welding since porosity is one of the most frequent causes of subpar MIG welds. A dirty or greasy surface may trap contaminants in the weld, resulting in sponge-like holes.

- To avoid porosity, clean your work surface thoroughly by removing any paint, dirt, oil, or rust, and grinding out any surface cracks. Additionally, using a deoxidizer in your wire may help prevent porosity.

Tip #3: Establish a solid grounding connection.

- To enhance your welding, it is critical to have a dependable ground clamp. Copper is an excellent electrical conductor and is frequently used to create high-quality ground clamps that are long-lasting. On the other hand, lower-quality clamps, such as plated steel ones with copper jaws, are not as effective as full copper ground clamps.

- Inadequate ground clamps may produce unpleasant noises and potentially harm your welding machine. To establish a consistent flow of electricity, place the clamp near the arc and secure it tightly to the clean, bare metal.

Tip #4: Ensure your MIG welder is properly set up.

- It is essential to adjust your welding machine every time you start a welding project. Begin by referring to the chart on the welding machine and adjusting the voltage and wire speed according to the thickness of the metal you intend to weld. However, these settings are just a starting point, and you should fine-tune them based on the weld quality.

- To test the wire, you may need to perform a few practice welds on scrap metal. If the wire is spitting, it means that it is feeding too quickly, so try reducing the wire speed or increasing the voltage. If the wire burns back to the tip or produces a glob, turn down the voltage or increase the wire speed.

Tip #5: Interpret your weld bead.

- Your weld bead can provide valuable feedback about your welding technique. If your bead has a convex shape and appears ropy, it suggests that your settings are too cold. To achieve proper penetration of the base metal, you need to increase the heat. Additionally, adjusting the welding angle by 5 or 10 degrees can also help with penetration.

- Conversely, a concave-shaped bead indicates that there is an issue with your heat input. It could mean that you are applying too much heat or moving the welding gun too slowly. In this case, you should adjust your settings or technique to achieve a flatter, more uniform bead.

MIG Welding Training & Practice

While these 5 tips provide a solid foundation for beginners learning MIG welding, there are still many other factors to consider as you advance. It’s essential to select the appropriate welding gas and wire, pay attention to the sounds emitted by the welder, and more.

In addition, it is important to ensure that you are using the appropriate welding gas and selecting the right type of wire for your project. You should also pay attention to the sounds produced by your welding machine and consider other factors that may affect the quality of your welds.

The most effective way to learn MIG welding is to practice regularly and seek guidance from experienced welders. Taking welding classes, particularly if you’re interested in learning other welding methods, can be extremely beneficial. Welding school offers an excellent opportunity to acquire welding basics.