How To MIG Welding Exhaust Pipe

MIG welding is better suited to welding exhaust pipes than flux-core and stick welding. However, it is not as ideal as TIG welding. No matter, you can still do a pretty good job with a solid MIG welder.

As with any other MIG welder task, you need to clean the base metal first. The exhaust tubing should be free of dust and rust. A metal brush will come in handy to clean the tubing and expose the bear metal.

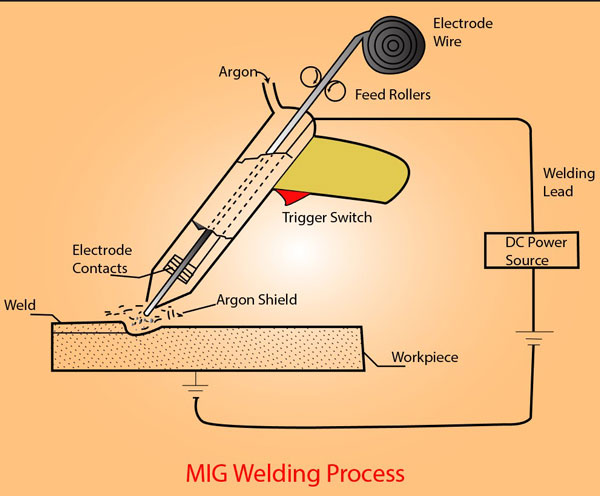

A combination of argon and carbon dioxide is recommended for MIG welding exhaust pipe. Additionally, setting the amperage range to medium will be essential to avoid burn through.

Advantages Of MIG Welding Exhaust Pipe

- You can produce high-quality welds much faster than with stick and flux core welding

- There is no need to worry about slag as there is no flux used when welding

- MIG welding is versatile and can be used with many different kinds of metal including alloys

- You can achieve MIG welding in a number of ways including full and semi-automatic

Disadvantages Of MIG Weld Exhaust

- Requires the use of an external shielding gas tank which can make the necessary equipment expensive

- You cannot use this welding technique outside or in windy conditions

Safety Tips For MIG Weld Exhaust

- Wear welding gloves as MIG welding tends to produce a hot arc

- Wear closed-toe shoes to prevent sparks from injuring your feet

- Use a welding mask to protect your face from fumes and UV rays produced when welding