How To Weld Exhaust Pipe With Stick Welding?

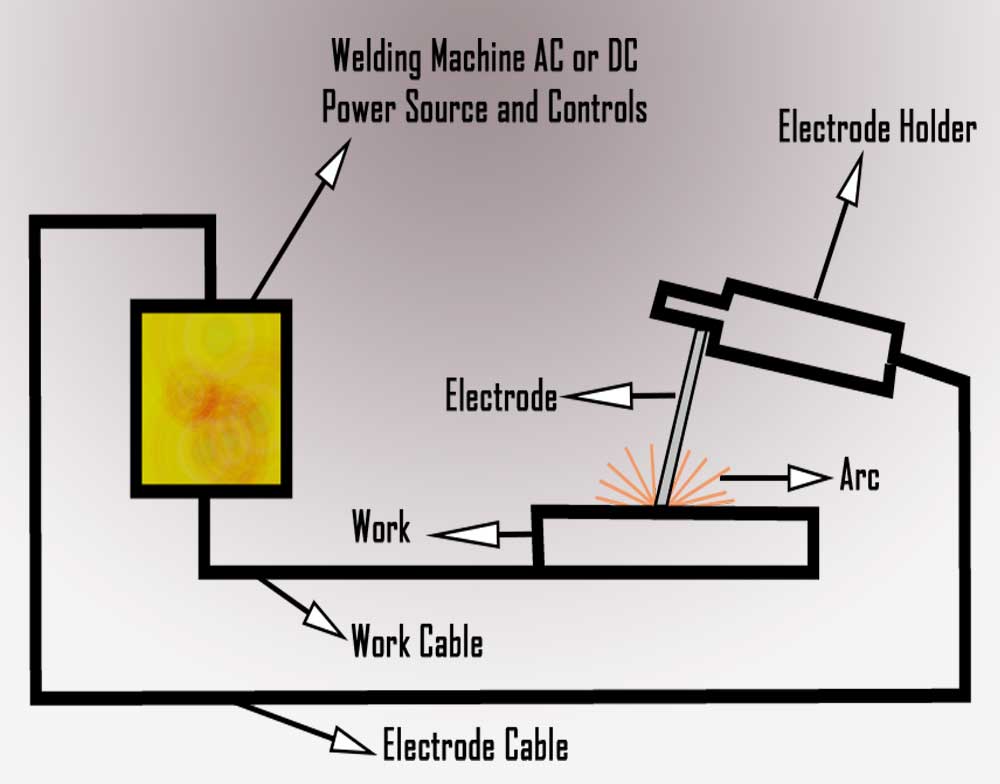

One of the first things you learn about exhaust pipe welding is that stick welders are not suited for the task. However, it is not impossible to weld exhaust pipe using a stick welder. Stick welding exhaust will require some bit of ingenuity.

First is knowing what kind of rod to use. The 6011 rod is the best for the job. Choose the thinnest 6011 rods you can find; a 1/16 will do. Use the same spot welding technique discussed above before welding around the tubing.

Before welding though, cleaning will be necessary. I know stick welding is not affected by rust, dirt, or paint, but cleaning is the best way to avoid slag.

Advantages Of Stick Welding Exhaust Pipe

- Stick welding can be done anywhere indoors and outside

- The equipment you need to stick weld is inexpensive and easy to use

- You can weld in in different weather conditions,

- Stick welding is less sensitive to rust, paint, and dirt

Disadvantages Of Stick Weld Exhaust

- Stick welding is known for producing slag which can lead to slag holes and leaks

- You will use a lot of electrodes as only a few inches can be welded with an electrode at a time.

Safety Tips For Stick Weld Exhaust

- Wear a welding mask and gloves to protect your eyes and skin from harmful UV light and fumes produced when stick welding.

- Weld in a well-ventilated room to protect yourself from the heavy fumes that emanate from your stick welder.

- Maintain a low amperage range to avoid burning through the thin exhaust tubing and overheating the stick welder

- Do not weld the exhaust pipe while it is still attached to the car as the sparks produced when welding can cause explosions