MIG-315L PRO Gas Gasless MIG Welding Machine – Advanced Features for Professionals

MIG welding is a popular welding technique used in various industries for its efficiency and versatility. The MIG-315L PRO Gas Gasless MIG Welding Machine is a cutting-edge welding tool that offers exceptional performance and flexibility.

The MIG-315L PRO presents numerous advantages as a 315 Amp MIG welder. One notable benefit is its compact and lightweight design, which facilitates easy maneuverability and transportation. As a result, this welding machine is well-suited for a variety of applications, whether in a workshop or on-site. Moreover, the welder incorporates an advanced cooling system that ensures efficient operation, minimizing downtime and extending its lifespan.

Features and Benefits of the MIG-315L PRO

Key Features:

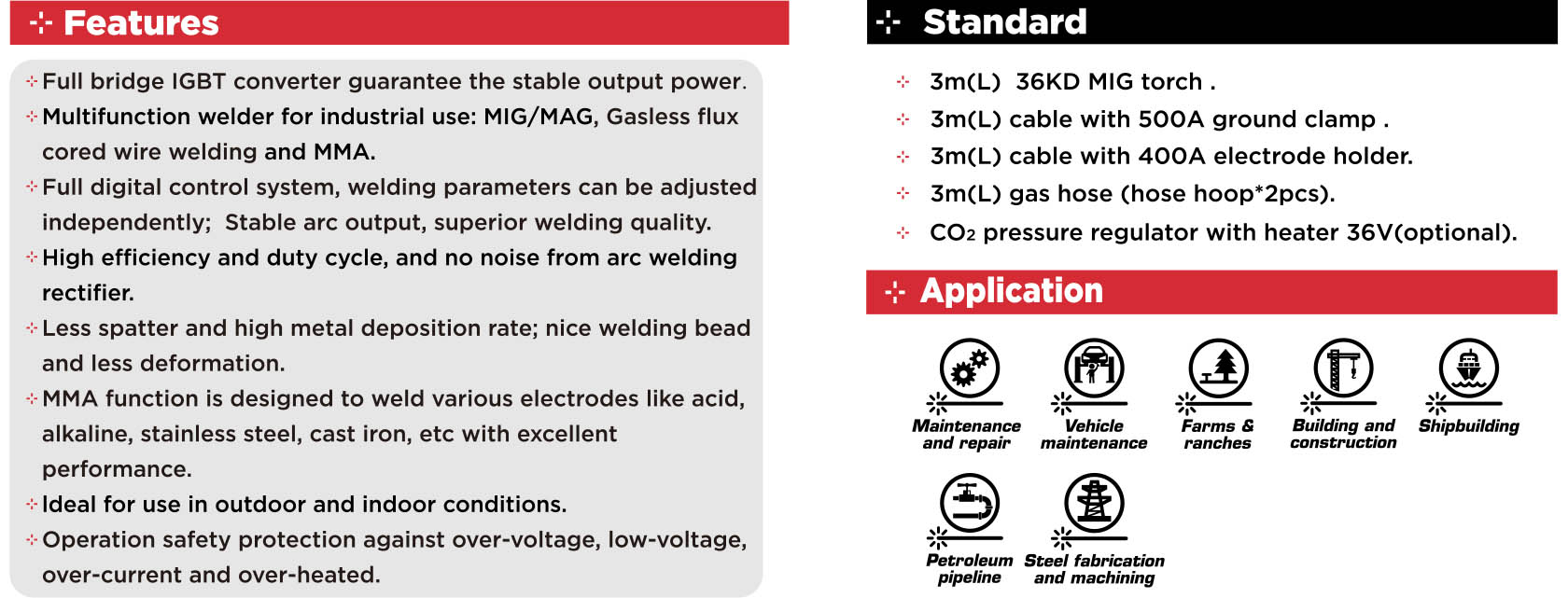

- Stable Output Power: The full bridge IGBT converter guarantees a stable output power, ensuring consistent performance during welding operations.

- Multifunctional Welder: This industrial-grade welder offers versatile capabilities, allowing for MIG/MAG, Gasless flux-cored wire welding, and MMA processes to be carried out.

- Full Digital Control System: The welder is equipped with a fully digital control system, enabling independent adjustment of welding parameters. This feature ensures a stable arc output and delivers superior welding quality.

- High Efficiency and Duty Cycle: The MIG-315L PRO operates with high efficiency and boasts an impressive duty cycle. Additionally, it produces minimal noise during arc welding due to its advanced rectifier.

- Reduced Spatter and High Deposition Rate: With this welder, users can expect less spatter and a high deposition rate, resulting in neat welding beads and minimal deformation.

- MMA Function: The MIG-315L PRO includes an MMA function designed to accommodate various electrodes, such as acid, alkaline, stainless steel, and cast iron. It delivers excellent performance across these applications.

- Suitable for Various Environments: This welding machine is suitable for both outdoor and indoor use, making it highly versatile for different work conditions.

- Enhanced Safety Features: The MIG-315L PRO incorporates safety protections against over-voltage, low-voltage, over-current, and overheating, ensuring the operator’s well-being and equipment longevity.

Introduction to the MIG-315L PRO Gas Gasless MIG Welding Machine

How to Use the MIG-315L PRO Welding Machine

Step 1: Setting up the welding machine

- Ensure the machine is placed on a stable surface and properly grounded.

- Connect the welding torch, ground clamp, and gas hose securely.

Step 2: Selecting the welding process (gas or gasless)

- Choose the appropriate welding process based on the material and project requirements.

- If using gas, connect the appropriate gas cylinder and adjust the flow rate accordingly.

Step 3: Adjusting the welding parameters

- Set the voltage, wire speed, and other welding parameters based on the material thickness and welding technique.

- Refer to the machine’s manual for recommended settings or consult an experienced welder.

Step 4: Preparing the workpiece and materials

- Clean the workpiece to remove any dirt, rust, or contaminants that can affect the welding quality.

- Ensure proper fit-up and alignment of the materials to be welded.

Step 5: Starting the welding process

- Position the torch at the desired starting point and initiate the arc by striking it against the workpiece.

- Maintain a steady travel speed and control the torch’s position and angle for consistent and even welds.

Step 6: Post-welding considerations

- Allow the weld to cool down naturally and inspect it for any defects or imperfections.

- Clean the weld area, removing any spatter or slag.

- Repeat the process for subsequent welds or adjust the parameters as necessary.

By following these steps and leveraging the advanced features of the MIG-315L PRO Gas Gasless MIG Welding Machine, you can achieve precise and high-quality welds in your projects. Experience the convenience and performance of this exceptional welding tool for your professional welding needs.