Small transformer type welding machines can have how low of a duty cycle?

Small transformer type welding machines typically have a relatively low duty cycle compared to larger industrial welding machines. Duty cycle refers to the percentage of time that a welding machine can operate within a specific time frame without overheating. It is an important consideration to prevent the machine from overheating and ensure its longevity.

Due to their smaller size and limited power output, small transformer type welding machines usually have a lower duty cycle. While duty cycles can vary depending on the specific model and manufacturer, it is common to find small transformer welding machines with duty cycles ranging from around 10% to 30%.

For example, a small transformer type welding machine with a 20% duty cycle means that it can operate continuously for 2 minutes out of a 10-minute cycle before needing to cool down. During the remaining 8 minutes, the machine should be allowed to cool down to prevent overheating.

It’s important to note that the duty cycle of a welding machine is influenced by various factors, including the ambient temperature, the welding current being used, and the machine’s overall design and construction. It’s advisable to consult the manufacturer’s specifications and guidelines for the specific welding machine in question to determine its exact duty cycle and ensure safe and optimal operation.

In summary, small transformer type welding machines typically have a lower duty cycle compared to larger industrial welding machines. The duty cycle can range from around 10% to 30%, depending on the specific model and manufacturer. Understanding the duty cycle is crucial to prevent overheating and ensure the longevity and safe operation of the welding machine.

FAQ:

Q: What is the duty cycle of welding machines?

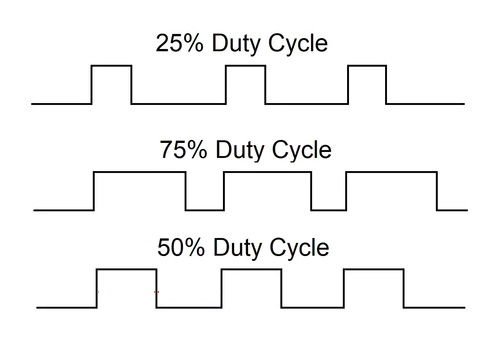

A: In the context of welding machines, the duty cycle refers to the amount of time a welding machine can operate within a specified time period without overheating. It is typically expressed as a percentage.

What is duty cycle

Welding machines generate intense heat to melt and fuse metals together. However, prolonged operation can cause the machine to overheat, potentially leading to damage or reduced performance. To prevent this, manufacturers specify a duty cycle rating for their welding machines.

The duty cycle rating represents the percentage of a specific time period (usually 10 minutes) that a welding machine can be operated continuously at its maximum output before it needs to cool down. For example, a welding machine with a duty cycle rating of 60% can be operated at its maximum output for 6 minutes within a 10-minute period before it requires a 4-minute cooldown.

It’s important to consider the duty cycle when selecting a welding machine for a specific application. Higher duty cycle machines are suitable for continuous or heavy-duty welding tasks, while lower-duty cycle machines may be sufficient for intermittent or lighter welding jobs. Exceeding the duty cycle of a welding machine can result in overheating and potential damage to the machine.

It’s worth noting that duty cycle ratings can vary among different welding machine models and manufacturers. Therefore, it’s essential to refer to the specifications provided by the manufacturer to determine the duty cycle and choose a welding machine that suits your specific welding needs.