The TIG Welding Process – Questions Answered for Your TIG Welding

What is TIG Welding?

The acronym TIG stands for Tungsten Inert Gas. Tungsten refers to the type of conductor (a tungsten electrode) that is used to transfer the welding current to the job and create the arc. Inert Gas refers to the fact that the process relies on an inert gas (eg Argon) to shield the weld and prevent weld oxidisation.

TIG is also referred to as Gas Tungsten Arc Welding (GTAW).

In simple terms, TIG welding is probably most similar to oxy flame welding. However, instead of a flame, it uses an electrical arc to melt the job and filler metal, and instead of a preheat flame it uses inert gas to prevent weld oxidisation. Like oxy flame welding, the filler metal is fed into the weld by hand as required. Due to the fact that the current is not conducted to the job via the filler metal, (as it is in MIG and MMA welding), the arc is much more controllable.

What are the Advantages of TIG welding?

Very low amperages can be achieved making this process ideal for welding thin materials. Also, due to the independence of the arc and the filler metal application, TIG welding is very controllable and can therefore achieve very high-quality welds with excellent appearance. Unlike MIG and MMA welding, TIG welding does not produce spatter so clean-up is very minimal.

TIG is typically used where weld appearance is critical (e.g. handrails) or where weld quality is vital (e.g. pressure vessels or pipes).

What are the Disadvantages of TIG welding?

Whilst TIG welding is very controllable, it can also be slower and more tedious than MIG or stick/MMA welding and it will generally not operate well on dirty or rusty materials meaning that additional weld preparation is sometimes necessary.

What Metals can I weld with TIG?

“DC” (Direct Current) TIG welding machines can be used to weld a variety of “ferrous metals” including mild steel & stainless steel, and also copper and chrome moly. (But NOT aluminium).

Many (but not all) inverter stick/MMA welders have DC TIG capabilities.

An important feature to enable effective TIG welding is lift-arc ignition.

To weld aluminium, you need a machine with “AC” (Alternating Current) capability.

Such machines usually have both AC and DC capability (“AC/DC”) in one machine – this allows them to weld most metals including; aluminium, steel, stainless steel, copper, chrome-moly, etc.

Typically AC/DC machines, such as the TIG-200DP TIG welding machine, are dedicated TIG welding machines (sometimes with stick/MMA capacity as an additional feature).

What Gas should be used when TIG welding?

Pure argon (100% Ar) is required for most common TIG welding applications. Some critical applications may require speciality gases.

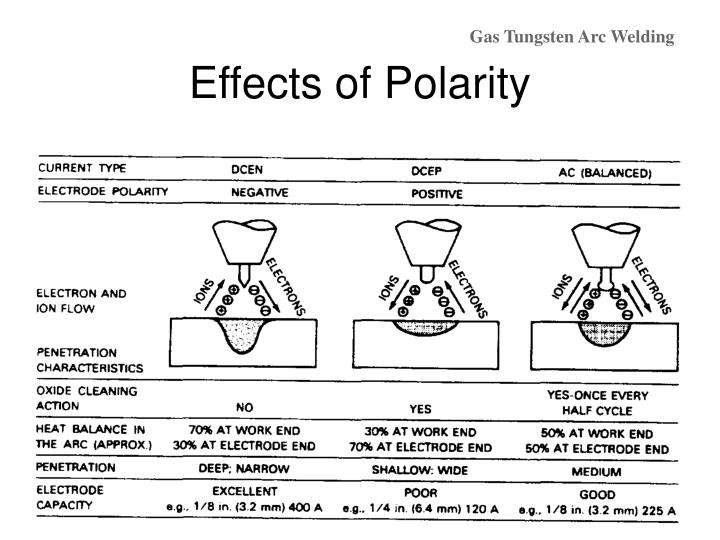

What is the correct Polarity when TIG welding?

Polarity refers to the direction of current flow when welding

Polarity refers to the direction of current flow when welding.

All DC TIG welding (steel, stainless, etc) is done on DC- polarity where the TIG torch is connected to the negative (-) terminal and the earth lead to the positive (+) terminal.

For AC TIG welding (aluminium) the polarity is usually* the opposite to DC: the TIG torch is connected to the positive (+) terminal and the earth lead to the negative (-) terminal.

*Note: Whilst “torch positive” is the most common polarity for AC/DC TIG welding, some AC/DC TIG machines may require “torch negative”. Consult the instruction manual for your machine, or contact the manufacturer.

What is the correct tungsten electrode for TIG welding?

Different types of TIG tungsten electrodes

Different types of TIG tungsten electrodes

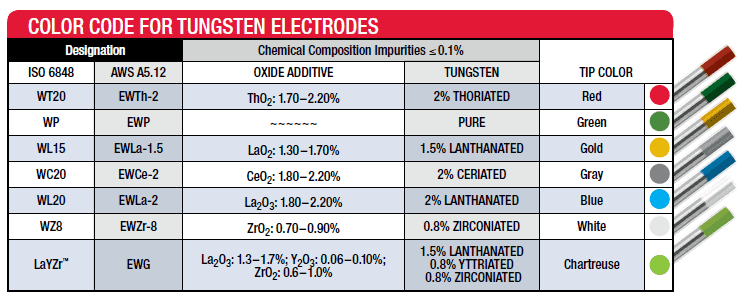

The most common tungsten electrode types are as follows;

Tungstens for DC TIG welding of steel, stainless steel, chrome molly, and copper:

Thoriated (red tip)

Lanthanated 1.5% (gold tip)

Tungstens for AC welding of Aluminium:

Zirconiated (white tip)

“All-Metal” Tungstens suitable for AC or DC welding:

Rare-earth (purple tip)

Lanthanated 2% (blue tip)

Ceriated (grey tip)

Material Thickness vs Amps vs Tungsten Size

Because of the many variables in any given TIG welding application, there is no single formula to say “for X thickness you need X amps”.

The many factors that influence this include; the material being welded, type of weld joint, weld position, operator technique, skill and/or experience, required strength or quality of the weld joint, etc.

However, here is a rough guide for TIG welding of steel, stainless or aluminium:

| Material Thickness* |

Suggested Tungsten Size* |

Amps Required* |

| <1mm | 1.0mm | 10-30A |

| 1-2mm | 1.6mm | 30-80A |

| 2-3mm | 2.4mm | 80-150A |

| 4-5mm | 3.2mm | 150-200A |

*This is a general guide only and should not be used as specific advice for any particular application